Quoi de neuf 2020

From Eric

(Difference between revisions)

m |

m |

||

| Line 12: | Line 12: | ||

** So there were two solutions: either recompiling the firmware with the appropriate step per unit configuration, or using the "M92 Z800" directive. | ** So there were two solutions: either recompiling the firmware with the appropriate step per unit configuration, or using the "M92 Z800" directive. | ||

** For the moment, I have simply changed the start G-code in Cura (Preferences/printers/Machine settings) and added "M92 Z800". Now, it seems that I am a bit underextruding. I have printed the calibration cube ([https://www.thingiverse.com/thing:3678579 here ]) and the faces are far too thin with the current 75% flow. | ** For the moment, I have simply changed the start G-code in Cura (Preferences/printers/Machine settings) and added "M92 Z800". Now, it seems that I am a bit underextruding. I have printed the calibration cube ([https://www.thingiverse.com/thing:3678579 here ]) and the faces are far too thin with the current 75% flow. | ||

| - | * April 17th | + | * April 17th and before |

** I am currently playing with Vue.js. My objective is to develop a small control interface for my robot. I have to say that building an HMI using Javascript and all the Web technologies is much much more efficient (in terms of development time) than using classical technologies! In a few hours (starting from a close-to-zero knowledge about Web techs), I have been able to create a small interface that displays the orientation of the robot in 3D (using three.js), plots some of its parameters (using Google Charts,) etc. | ** I am currently playing with Vue.js. My objective is to develop a small control interface for my robot. I have to say that building an HMI using Javascript and all the Web technologies is much much more efficient (in terms of development time) than using classical technologies! In a few hours (starting from a close-to-zero knowledge about Web techs), I have been able to create a small interface that displays the orientation of the robot in 3D (using three.js), plots some of its parameters (using Google Charts,) etc. | ||

| - | + | * UsineAGazBot,my robot has done its first steps! | |

| - | + | * It is fitted with... 2 arduino pro mini, one arduino due, one arduino mega, one ESP32, one Raspberry Pi, one FPGA (Tang Nano), and one Jeston nano!, all these guys being connected via a CAN network. | |

| - | + | * Surely, it is overkill, but I wanted to add functions one y one, incrementally, each of them beig hosted by its own CPU. Later, I'll try to make them fit in slightly less silicium. | |

| - | + | * For the moment, it is completely remotely operated, but it is built using ROS and there shouln't be that many difficulties to make it autonomous. | |

| - | + | * Here are a few pictures of the beast (I admit that it is difficult to find where's the front, where's the bottom...): | |

| - | + | ||

| - | + | ||

[[File:usineagazbot-1.jpg|400px|thumb|none]] | [[File:usineagazbot-1.jpg|400px|thumb|none]] | ||

[[File:usineagazbot-2.jpg|400px|thumb|none]] | [[File:usineagazbot-2.jpg|400px|thumb|none]] | ||

| - | + | * I have finally managed to make my Ender 5 work: it was simply overextruding. By reducing the extrusion speed by 20%, it works just fine. I certainly have to calibrate the mm/step but, as it works... By the way, as my bed is not level, I use babystepping to ensure that the first layer sticks to the bed. This is manual, but not that complicated. | |

== Mars 2020 == | == Mars 2020 == | ||

* Covid 19 quarantine | * Covid 19 quarantine | ||

* I have updated by Ender 5 3D printer with the latest version of Marlin. I have basically followed the indicated given by TeachingTech, [https://www.youtube.com/watch?v=aQIg9zxuCvM&t=275s here]. I have had some difficulties when updating the firmware using the Arduino ISP. The trick was (i) to use a high quality USB cable, (ii) to place a 100uF capacitor between the reset pin and the ground on the Arduino. Once done, there was no problem to install the bootloader. Then I used the modified Marling configuration files proposed by TeachingTech. In order to add manual mesh leveling, I have uncommented the following #defines: MESH_BED_LEVELING, RESTORE_LEVELING_AFTER_G28 and LCD_BED_LEVELING in Configuration.h. Then I have commented ARC_SUPPORT (Configuration_adv.h) otherwise the binary was too big. And that's it. | * I have updated by Ender 5 3D printer with the latest version of Marlin. I have basically followed the indicated given by TeachingTech, [https://www.youtube.com/watch?v=aQIg9zxuCvM&t=275s here]. I have had some difficulties when updating the firmware using the Arduino ISP. The trick was (i) to use a high quality USB cable, (ii) to place a 100uF capacitor between the reset pin and the ground on the Arduino. Once done, there was no problem to install the bootloader. Then I used the modified Marling configuration files proposed by TeachingTech. In order to add manual mesh leveling, I have uncommented the following #defines: MESH_BED_LEVELING, RESTORE_LEVELING_AFTER_G28 and LCD_BED_LEVELING in Configuration.h. Then I have commented ARC_SUPPORT (Configuration_adv.h) otherwise the binary was too big. And that's it. | ||

Revision as of 16:27, 1 May 2020

Experiments carried out in the past (from 2011) are described hereafter: 2019, 2018, 2017, 2015, 2014, 2013, 2012, 2011

May 2020

- Still locked at home...

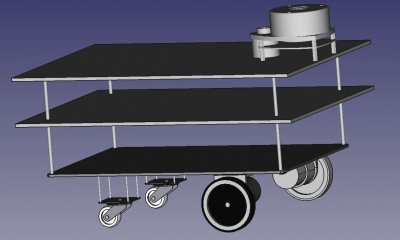

- I am curently creating a simple URDF model of my robot in order to generate transformations (from base link to the LIDAR, to the camera, etc.) automatically.

- So I have first modelled it (partially) with FreeCad:

April 2020

- April 18th

- I used to think that my Ender 5 was printing correctly... but no! By playing on the filament flow, I was able to prevent the head bumping on the printed surface. But the problem was NOT over-extrusion!

The actual problem comes from the fact that there are two versions of the Ender5, with two different z-screw: one with 400 steps per cm and the other with 800 steps per cm. I own the second one but the default Marlin firmware for the Ender comes with the 400 steps / cm configuration (see file "Configuration.h", parameter "DEFAULT_AXIS_STEPS_PER_UNIT").

- So there were two solutions: either recompiling the firmware with the appropriate step per unit configuration, or using the "M92 Z800" directive.

- For the moment, I have simply changed the start G-code in Cura (Preferences/printers/Machine settings) and added "M92 Z800". Now, it seems that I am a bit underextruding. I have printed the calibration cube (here ) and the faces are far too thin with the current 75% flow.

- April 17th and before

- I am currently playing with Vue.js. My objective is to develop a small control interface for my robot. I have to say that building an HMI using Javascript and all the Web technologies is much much more efficient (in terms of development time) than using classical technologies! In a few hours (starting from a close-to-zero knowledge about Web techs), I have been able to create a small interface that displays the orientation of the robot in 3D (using three.js), plots some of its parameters (using Google Charts,) etc.

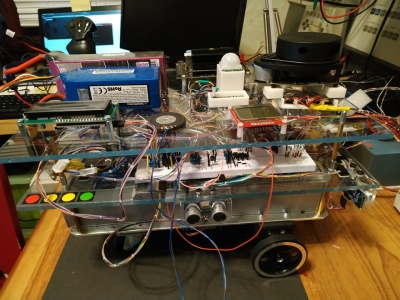

- UsineAGazBot,my robot has done its first steps!

- It is fitted with... 2 arduino pro mini, one arduino due, one arduino mega, one ESP32, one Raspberry Pi, one FPGA (Tang Nano), and one Jeston nano!, all these guys being connected via a CAN network.

- Surely, it is overkill, but I wanted to add functions one y one, incrementally, each of them beig hosted by its own CPU. Later, I'll try to make them fit in slightly less silicium.

- For the moment, it is completely remotely operated, but it is built using ROS and there shouln't be that many difficulties to make it autonomous.

- Here are a few pictures of the beast (I admit that it is difficult to find where's the front, where's the bottom...):

- I have finally managed to make my Ender 5 work: it was simply overextruding. By reducing the extrusion speed by 20%, it works just fine. I certainly have to calibrate the mm/step but, as it works... By the way, as my bed is not level, I use babystepping to ensure that the first layer sticks to the bed. This is manual, but not that complicated.

Mars 2020

- Covid 19 quarantine

- I have updated by Ender 5 3D printer with the latest version of Marlin. I have basically followed the indicated given by TeachingTech, here. I have had some difficulties when updating the firmware using the Arduino ISP. The trick was (i) to use a high quality USB cable, (ii) to place a 100uF capacitor between the reset pin and the ground on the Arduino. Once done, there was no problem to install the bootloader. Then I used the modified Marling configuration files proposed by TeachingTech. In order to add manual mesh leveling, I have uncommented the following #defines: MESH_BED_LEVELING, RESTORE_LEVELING_AFTER_G28 and LCD_BED_LEVELING in Configuration.h. Then I have commented ARC_SUPPORT (Configuration_adv.h) otherwise the binary was too big. And that's it.